advanced spc wall panel largescale production

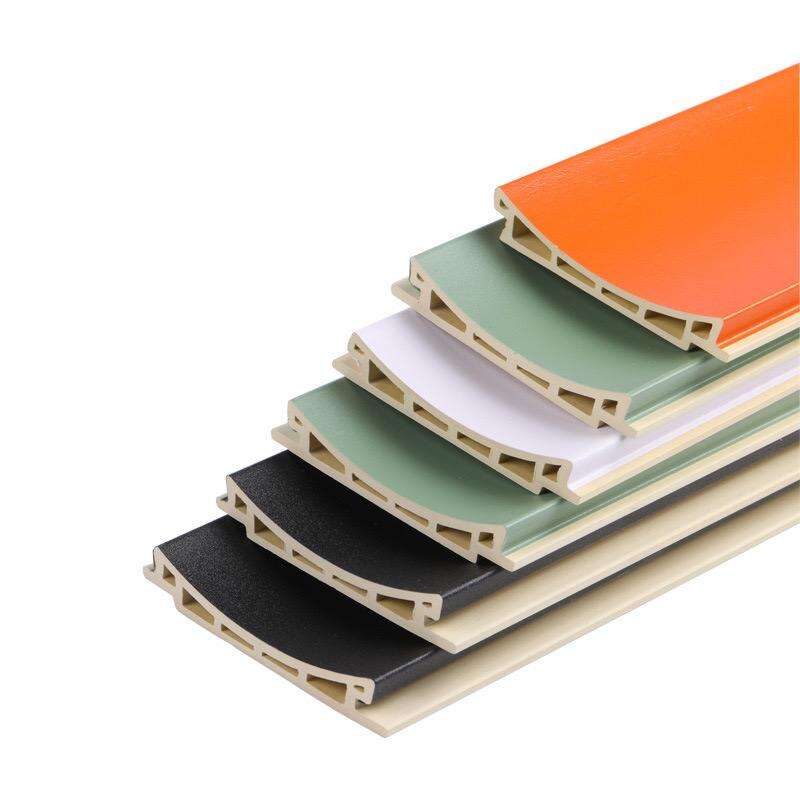

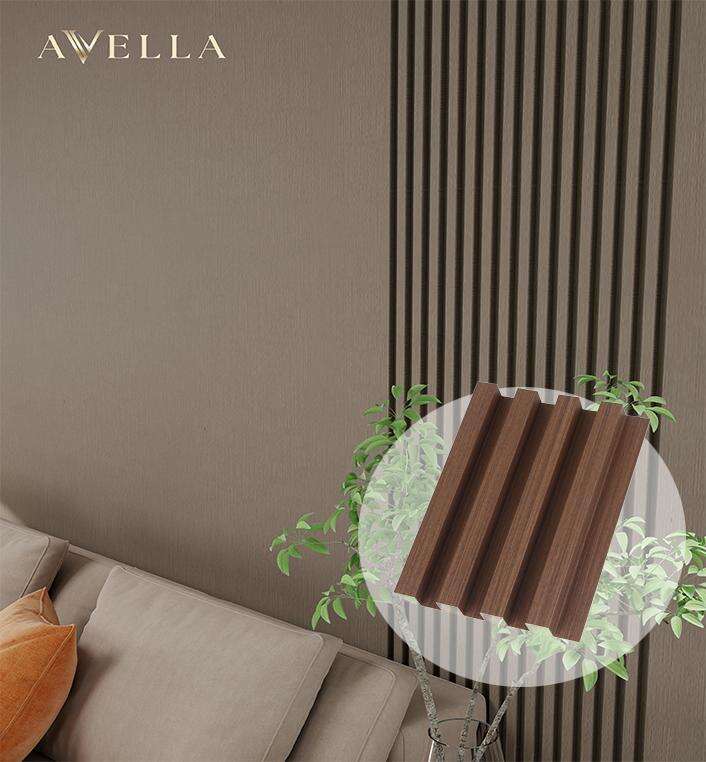

Advanced SPC wall panel largescale production represents a revolutionary approach to manufacturing stone plastic composite wall panels that combines cutting-edge technology with efficient mass production capabilities. This sophisticated manufacturing process utilizes state-of-the-art equipment and innovative techniques to produce high-quality wall panels at unprecedented volumes, meeting the growing global demand for durable, aesthetically pleasing interior wall solutions. The advanced SPC wall panel largescale production system integrates multiple manufacturing stages, including material preparation, extrusion, calendering, surface treatment, and quality control, all optimized for maximum efficiency and consistent output quality. The main functions of this production system encompass automated material mixing, precise temperature control during extrusion, multi-layer lamination processes, and comprehensive quality assurance protocols. Technological features include computer-controlled production lines, real-time monitoring systems, advanced cooling mechanisms, and automated cutting and packaging systems that ensure dimensional accuracy and surface finish consistency. The production process begins with the careful blending of limestone powder, polyvinyl chloride resin, and stabilizers, followed by high-temperature extrusion that creates the core substrate. Subsequently, decorative layers featuring realistic wood, stone, or abstract patterns are applied through advanced printing and embossing techniques. Applications for these wall panels span residential, commercial, and institutional markets, including hotels, offices, retail spaces, healthcare facilities, and modern homes. The advanced SPC wall panel largescale production system enables manufacturers to achieve economies of scale while maintaining strict quality standards, resulting in cost-effective solutions for interior designers, contractors, and property developers. This manufacturing approach supports customization options, allowing for varied thicknesses, surface textures, and decorative patterns to meet diverse architectural requirements and aesthetic preferences across different market segments.