oem spc flooring

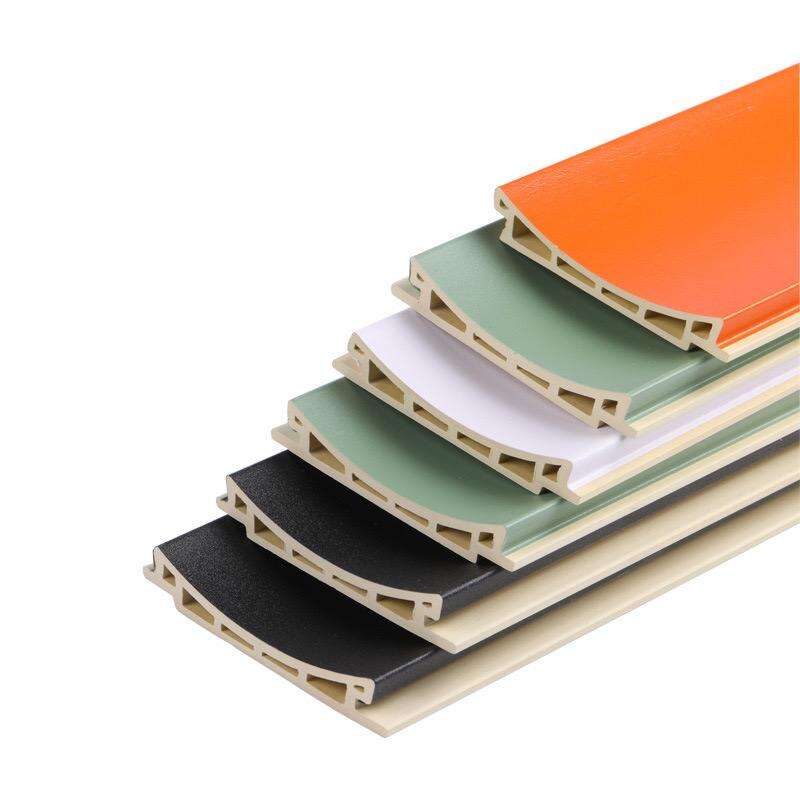

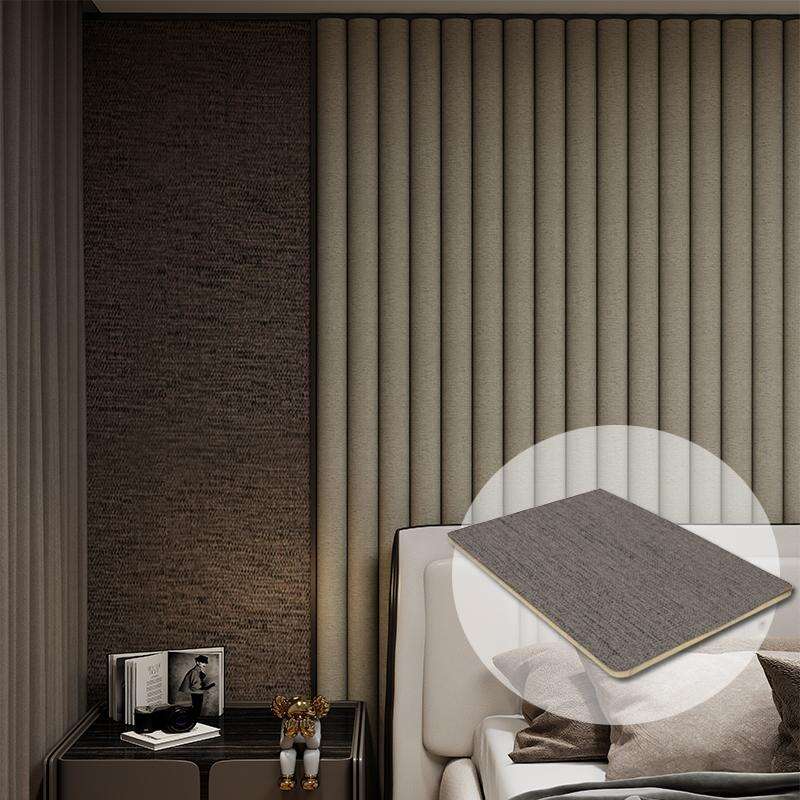

OEM SPC flooring represents a revolutionary advancement in modern flooring solutions, combining innovative stone plastic composite technology with original equipment manufacturing excellence. This cutting-edge flooring system utilizes a unique multi-layer construction that delivers exceptional durability, waterproof performance, and aesthetic versatility for residential and commercial applications. The core structure of OEM SPC flooring consists of a rigid stone plastic composite base layer, featuring a blend of natural limestone powder, polyvinyl chloride, and stabilizers that create an incredibly stable foundation. This technological foundation ensures dimensional stability, preventing expansion and contraction issues commonly associated with traditional flooring materials. The manufacturing process involves precision engineering and quality control measures that guarantee consistent product specifications and superior performance characteristics. OEM SPC flooring incorporates advanced wear layer technology, typically ranging from 0.3mm to 0.7mm thickness, providing outstanding resistance against scratches, stains, and daily wear patterns. The decorative layer features high-resolution printing technology that accurately reproduces natural wood grains, stone textures, and contemporary design patterns with remarkable authenticity. Installation versatility stands as a key technological feature, with most OEM SPC flooring products utilizing click-lock or tongue-and-groove systems that enable floating installation methods without requiring adhesives or extensive subfloor preparation. The waterproof core construction makes OEM SPC flooring suitable for moisture-prone environments including bathrooms, kitchens, basements, and commercial spaces where traditional hardwood or laminate flooring would fail. Applications span across diverse sectors including residential homes, retail establishments, healthcare facilities, educational institutions, and hospitality venues. The thermal stability of OEM SPC flooring allows compatibility with radiant heating systems, expanding installation possibilities for energy-efficient building designs. Quality assurance protocols in OEM manufacturing ensure each plank meets stringent performance standards for impact resistance, indentation recovery, and color stability under UV exposure.