Exceptional Design Versatility and Aesthetic Appeal

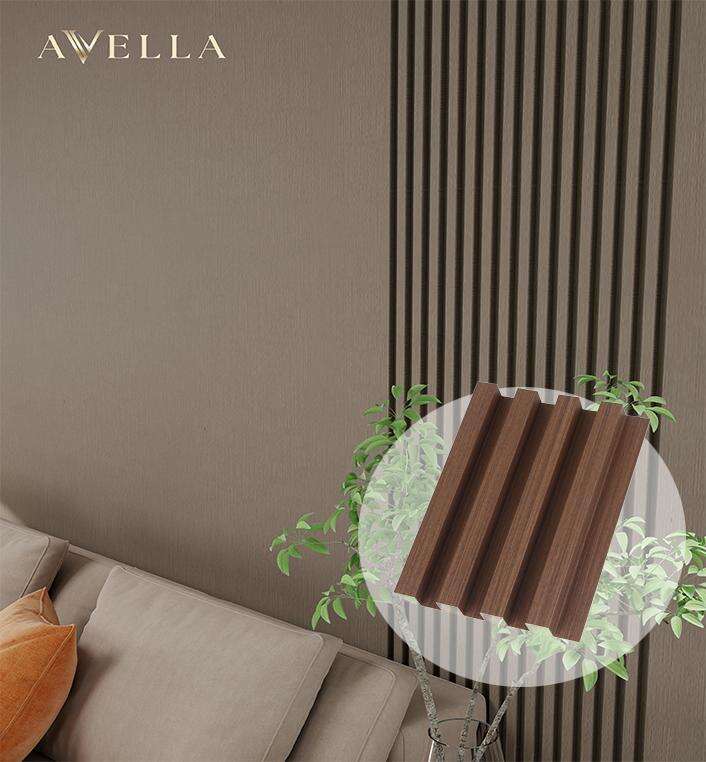

The remarkable design flexibility of PVC panels enables architects and designers to achieve virtually any aesthetic vision while maintaining the practical benefits of modern polymer technology. Advanced manufacturing techniques create authentic textures that convincingly replicate natural materials including wood grain patterns, stone surfaces, and contemporary smooth finishes. Digital printing technology allows for custom colors, patterns, and even photographic images to be permanently bonded to panel surfaces. The extensive range of standard finishes includes options that complement traditional, transitional, and ultra-modern design schemes without compromising performance characteristics. Color stability ensures that selected finishes maintain their appearance throughout the panel's service life, eliminating the fading and discoloration common with other materials. Surface textures range from high-gloss contemporary looks to matte finishes that minimize glare in office environments or educational facilities. The ability to mix and match different panel styles within the same project creates dynamic visual interest while maintaining installation consistency. Architectural details such as chair rails, crown molding, and baseboards are available in matching PVC materials, creating cohesive design schemes. Custom sizing capabilities accommodate unique architectural requirements, from standard residential wall heights to commercial applications with specialized dimensions. The three-dimensional texturing possible with PVC manufacturing creates realistic depth and shadow effects that enhance visual appeal. Light reflectance properties can be controlled through surface treatments, allowing designers to optimize illumination characteristics for specific applications. Pattern matching between panels ensures seamless visual flow across large installations, maintaining design integrity regardless of project scale. The material accepts standard architectural hardware such as picture hanging systems, display mounting, and decorative elements without special fasteners or reinforcement. Professional finishing options include beveled edges, rounded corners, and custom profiles that integrate seamlessly with existing architectural elements. Quality control processes ensure color consistency between production runs, allowing for future additions or repairs that match existing installations perfectly. The versatility extends to curved installations where the material can be thermoformed to follow architectural contours while maintaining structural properties.