spc flooring manufacturer

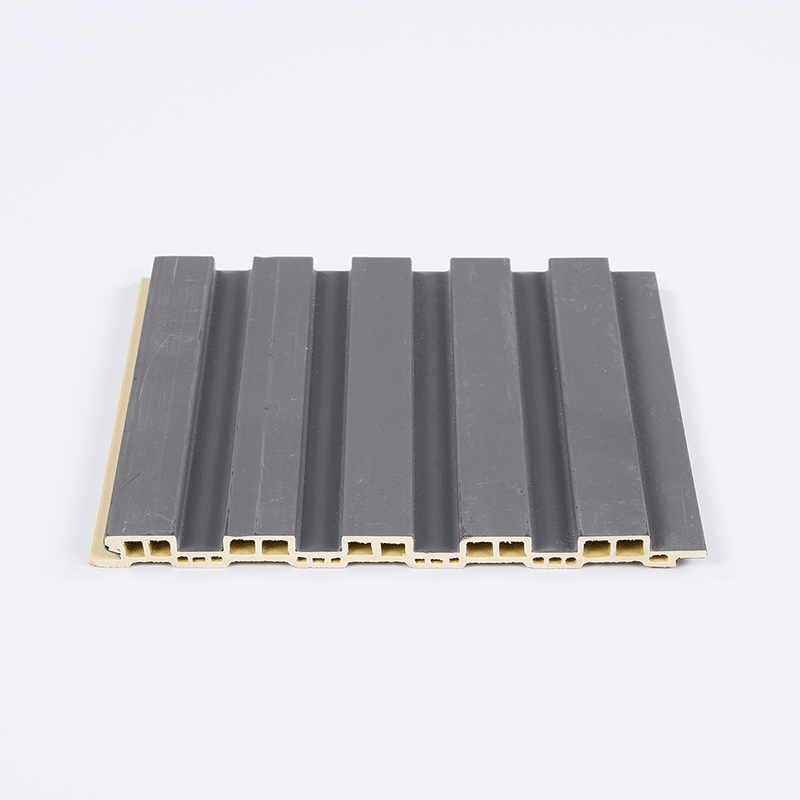

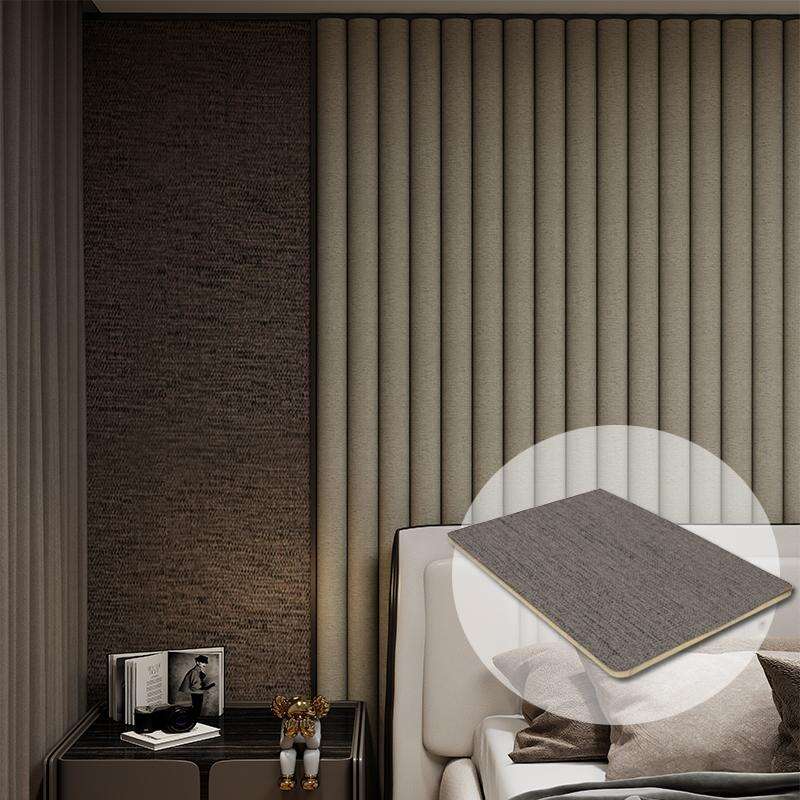

An SPC flooring manufacturer represents a cutting-edge company that specializes in producing Stone Plastic Composite flooring, one of the most innovative and durable flooring solutions available in today's market. These manufacturers utilize advanced production techniques to create flooring products that combine limestone powder, polyvinyl chloride, and stabilizers into a rigid core structure that delivers exceptional performance across residential and commercial applications. The primary function of an SPC flooring manufacturer involves engineering floors that resist moisture, scratches, and temperature fluctuations while maintaining dimensional stability under various environmental conditions. The technological features employed by leading SPC flooring manufacturers include precision extrusion processes, multi-layer construction methods, and sophisticated wear layer applications that enhance product longevity. These companies integrate state-of-the-art machinery capable of producing consistent thickness, seamless surface textures, and authentic wood or stone visual patterns through advanced printing technologies. Modern SPC flooring manufacturers focus on creating products with enhanced click-lock installation systems, enabling faster and more efficient installations for contractors and homeowners alike. The applications for products from an SPC flooring manufacturer span numerous sectors including residential homes, commercial offices, retail spaces, healthcare facilities, educational institutions, and hospitality venues. These versatile flooring solutions excel in high-traffic areas where traditional materials might fail, making them ideal for kitchens, bathrooms, basements, and commercial environments. Quality SPC flooring manufacturers implement rigorous testing protocols to ensure their products meet international standards for fire resistance, formaldehyde emissions, and structural integrity. The manufacturing process typically involves creating a rigid core layer, applying decorative films, adding protective wear layers, and finishing with specialized coatings that enhance stain resistance and ease of maintenance. Leading SPC flooring manufacturers continuously invest in research and development to improve product formulations, expand design options, and incorporate sustainable materials into their production processes.