spc wall panel fabrication

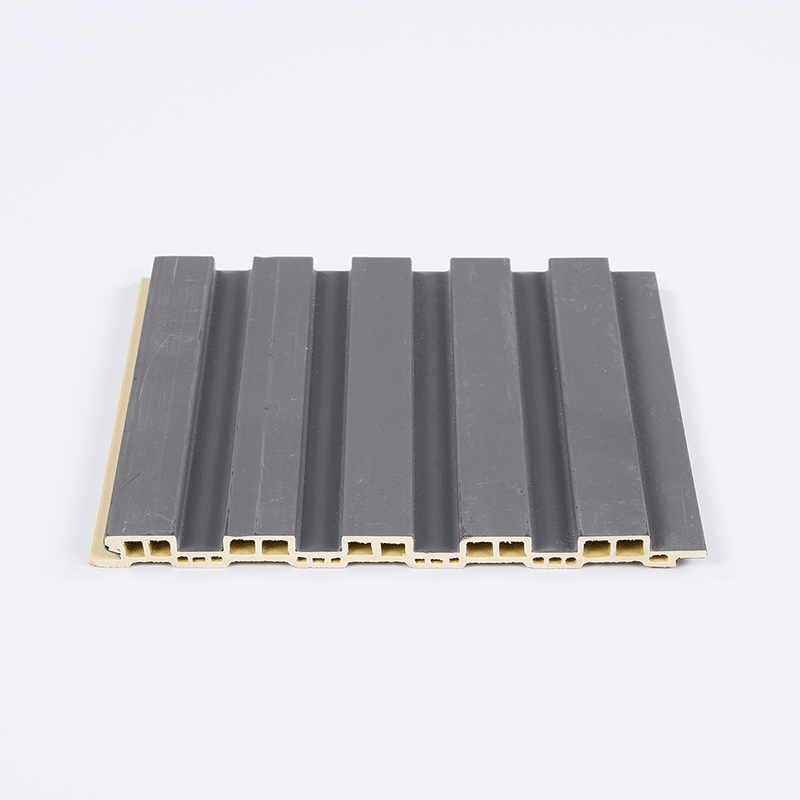

SPC wall panel fabrication represents a revolutionary advancement in modern construction materials, combining Stone Plastic Composite technology with innovative manufacturing processes to create superior wall covering solutions. This cutting-edge fabrication method involves the precise integration of limestone powder, polyvinyl chloride, and stabilizers through advanced extrusion techniques, resulting in panels that deliver exceptional performance characteristics. The spc wall panel fabrication process begins with careful material selection, where high-quality limestone is ground into fine powder and mixed with premium PVC resins under controlled conditions. During fabrication, specialized machinery applies intense heat and pressure to create a dense, uniform core structure that forms the foundation of each panel. The manufacturing process incorporates multiple layers, including a rigid SPC core, high-definition decorative film, and protective wear layers that enhance both aesthetics and functionality. Modern spc wall panel fabrication facilities utilize computer-controlled systems to ensure consistent quality and precise dimensional accuracy throughout production. The technological features of this fabrication process include thermal welding capabilities, click-lock installation systems, and advanced surface treatments that resist moisture, scratches, and fading. These panels serve diverse applications across residential, commercial, and institutional projects, offering versatile solutions for interior wall covering needs. The fabrication process enables customization of panel dimensions, surface textures, and decorative patterns to meet specific architectural requirements. Quality control measures integrated into spc wall panel fabrication ensure each panel meets stringent industry standards for structural integrity, fire resistance, and environmental safety. The sophisticated manufacturing approach allows for rapid production cycles while maintaining exceptional consistency in material properties and visual appearance, making these panels ideal for large-scale construction projects requiring reliable, high-performance wall covering solutions.