spc wall panel factory

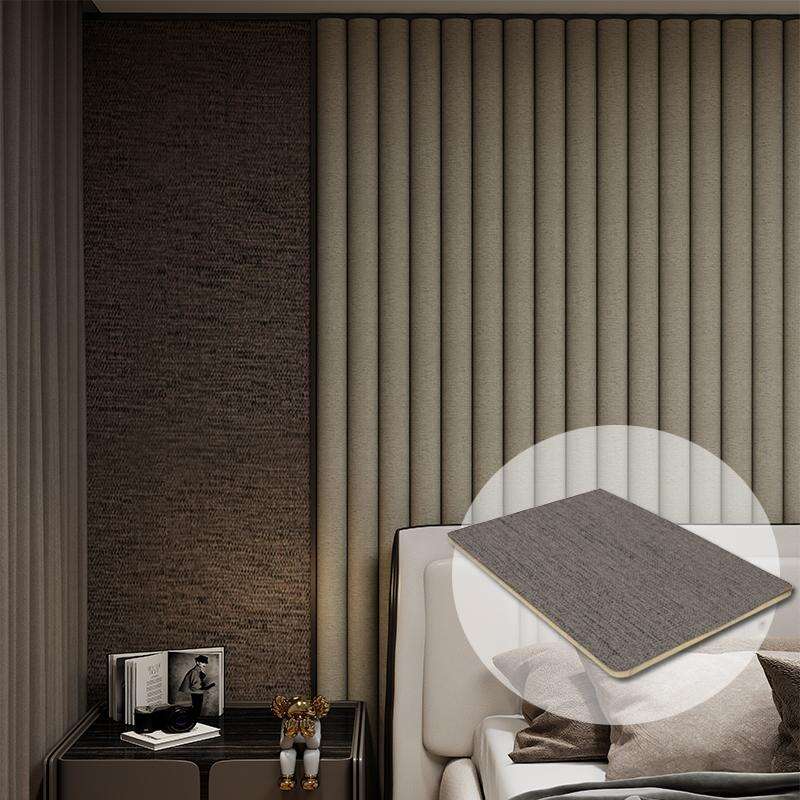

The SPC wall panel factory represents a cutting-edge manufacturing facility dedicated to producing Stone Plastic Composite wall panels, which have revolutionized interior design and construction applications. These specialized production centers combine advanced technology with innovative materials to create durable, versatile wall covering solutions that meet modern architectural demands. The SPC wall panel factory utilizes sophisticated extrusion processes, precision cutting equipment, and quality control systems to manufacture panels that offer superior performance characteristics. The primary function of an SPC wall panel factory involves transforming raw materials including limestone powder, polyvinyl chloride resin, and stabilizers into finished wall panels through controlled heating, mixing, and molding processes. The technological features of these manufacturing facilities include automated production lines equipped with twin-screw extruders, calendering machines, UV coating applications, and digital printing systems that enable realistic texture reproduction. Quality assurance protocols within the SPC wall panel factory ensure consistent thickness, dimensional stability, and surface quality across all products. The factory typically incorporates environmental controls to maintain optimal temperature and humidity levels throughout the production cycle. Modern SPC wall panel factories also feature integrated testing laboratories where products undergo rigorous evaluation for durability, fire resistance, and environmental compliance. Applications for SPC wall panels manufactured in these facilities span residential, commercial, and industrial sectors, including bathroom installations, kitchen backsplashes, accent walls, and high-traffic commercial spaces. The versatility of products from an SPC wall panel factory makes them suitable for both new construction and renovation projects, offering architects and designers flexible solutions for creating distinctive interior environments.