spc wall panel oem manufacturer

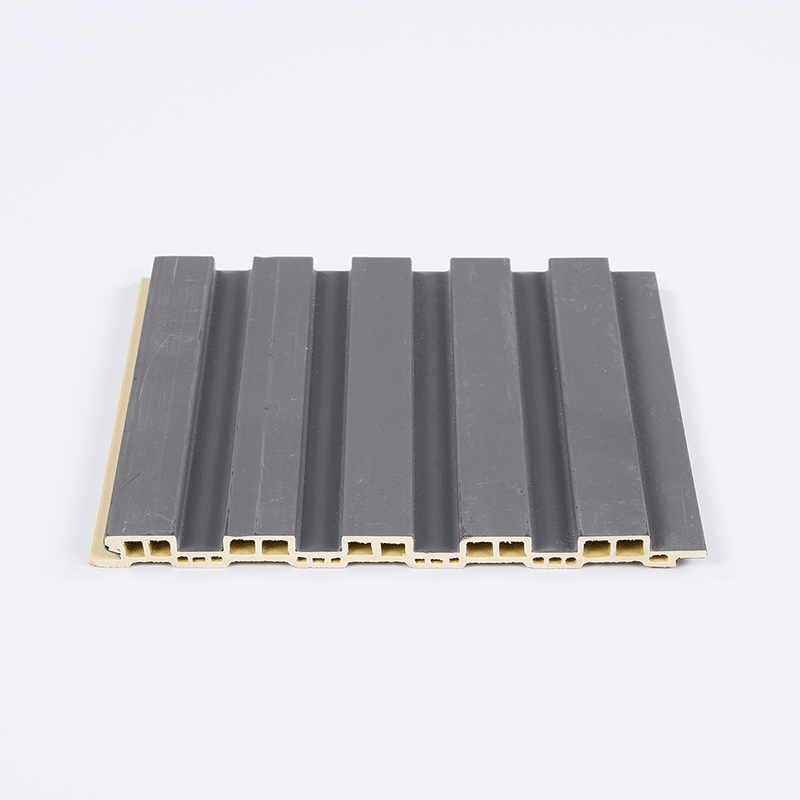

An SPC wall panel OEM manufacturer represents a specialized company that produces Stone Plastic Composite wall panels for businesses seeking private label solutions or bulk manufacturing services. These manufacturers combine advanced polymer technology with stone powder to create durable, versatile wall covering products that serve residential, commercial, and industrial applications. The primary function of an SPC wall panel OEM manufacturer involves developing customized wall panel solutions that meet specific client requirements while maintaining consistent quality standards and competitive pricing structures. The technological features of modern SPC wall panel OEM manufacturers include state-of-the-art extrusion equipment, precision cutting machinery, and automated quality control systems that ensure dimensional accuracy and surface consistency. These facilities typically incorporate advanced mixing technologies that blend virgin PVC resin with calcium carbonate and stabilizing additives to create panels with superior structural integrity and weather resistance. Many SPC wall panel OEM manufacturers utilize computer-controlled production lines that can accommodate various panel thicknesses, widths, and surface textures according to client specifications. The manufacturing process often includes multi-layer construction techniques that enhance thermal insulation properties and acoustic performance. Applications for SPC wall panels produced by OEM manufacturers span numerous sectors including residential construction, commercial buildings, healthcare facilities, educational institutions, and retail environments. These panels serve as interior wall cladding, exterior facades, bathroom surrounds, kitchen backsplashes, and decorative accent walls. The versatility of SPC materials allows manufacturers to create panels suitable for high-moisture environments, high-traffic areas, and spaces requiring frequent cleaning or sanitization. Professional SPC wall panel OEM manufacturers maintain comprehensive testing laboratories to verify product performance against industry standards for fire resistance, impact strength, and dimensional stability under various environmental conditions.