spc wall panel oem service

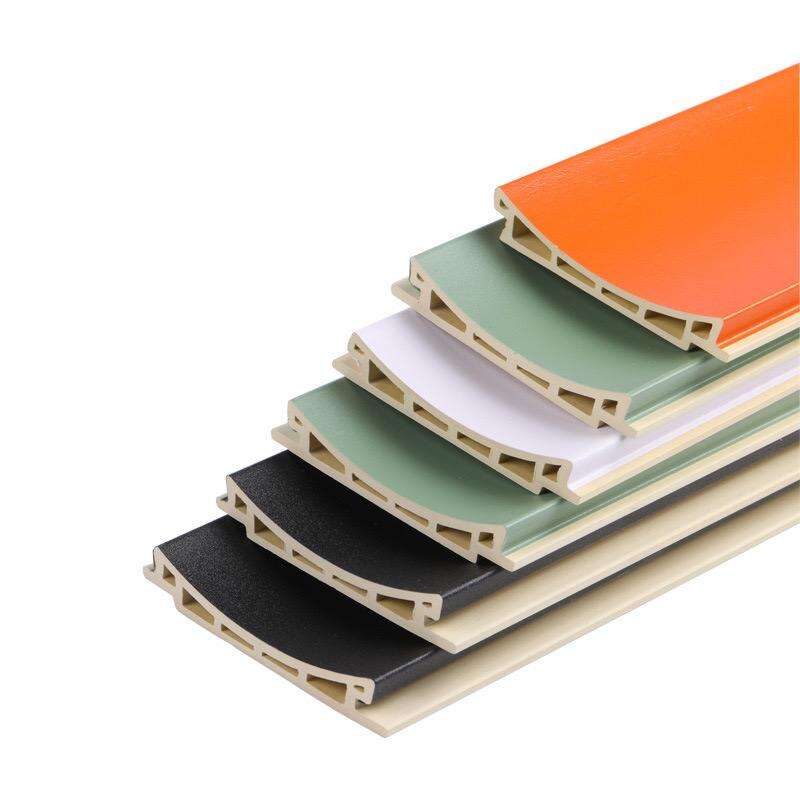

The spc wall panel oem service represents a comprehensive manufacturing solution that transforms architectural visions into reality through advanced production capabilities and customization expertise. SPC, which stands for Stone Polymer Composite, combines limestone, polyvinyl chloride, and stabilizers to create durable, waterproof wall panels that meet diverse construction and design requirements. This oem service encompasses the entire production pipeline, from initial design consultation and material selection to final product delivery and quality assurance. The technological foundation of the spc wall panel oem service relies on state-of-the-art extrusion and calendering processes that ensure consistent thickness, superior surface finish, and exceptional dimensional stability. Advanced digital printing technology enables manufacturers to reproduce intricate patterns, textures, and colors with remarkable precision, allowing clients to achieve their exact aesthetic goals. The service includes comprehensive mold development capabilities, enabling the creation of unique profiles and surface textures that differentiate products in competitive markets. Quality control systems integrated throughout the manufacturing process ensure that every panel meets stringent industry standards for durability, fire resistance, and environmental safety. The spc wall panel oem service extends beyond basic manufacturing to include packaging design, logistics coordination, and technical support services that facilitate smooth project implementation. Modern production facilities equipped with automated cutting, edge sealing, and finishing equipment can accommodate both small-batch custom orders and large-scale commercial projects. The service framework includes material sourcing from certified suppliers, ensuring consistent raw material quality and reliable supply chains. Environmental considerations are integral to the spc wall panel oem service, with recycling programs and sustainable manufacturing practices that minimize waste and reduce environmental impact. Technical documentation, installation guidelines, and ongoing customer support complete the service offering, providing clients with comprehensive solutions that extend well beyond the initial manufacturing phase.