wpc panel

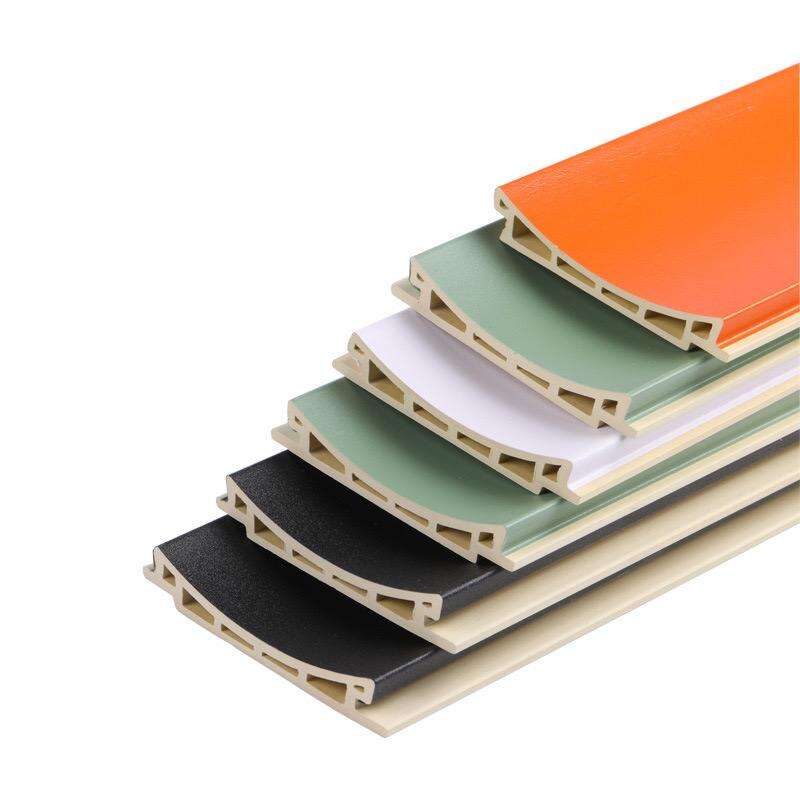

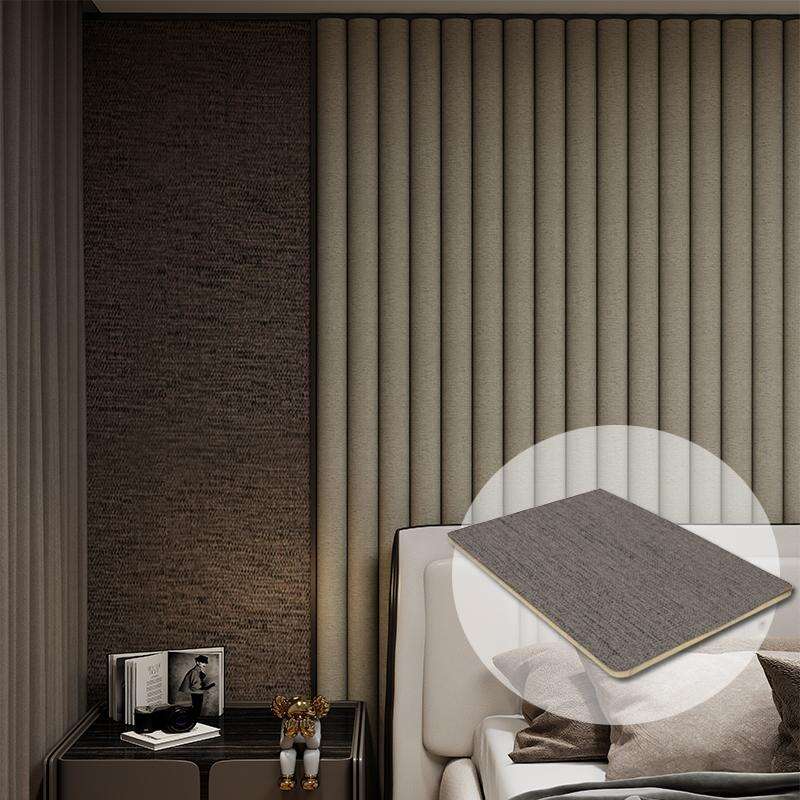

WPC panel, short for Wood-Plastic Composite panel, represents a revolutionary building material that combines the natural beauty of wood with the durability of synthetic materials. This innovative composite material consists of wood fibers or flour mixed with thermoplastic resins, creating a versatile solution for modern construction and design needs. The manufacturing process involves heating and molding these components under controlled conditions, resulting in panels that exhibit superior performance characteristics compared to traditional materials. WPC panel technology has emerged as a game-changing solution in the construction industry, offering architects and builders unprecedented flexibility in design applications. The composite structure provides exceptional resistance to moisture, insects, and decay, making it ideal for both indoor and outdoor installations. These panels maintain dimensional stability across various temperature ranges, ensuring long-term performance without warping or splitting. The surface texture can be customized to mimic natural wood grain or achieve smooth contemporary finishes, catering to diverse aesthetic preferences. WPC panel applications span residential, commercial, and industrial sectors, including wall cladding, flooring, decking, furniture manufacturing, and decorative elements. The material's workability allows for standard woodworking tools and techniques, simplifying installation processes for contractors and DIY enthusiasts. Environmental consciousness drives much of the appeal, as WPC panel production often incorporates recycled materials, reducing waste and promoting sustainability. The panels demonstrate excellent fire resistance properties and emit minimal volatile organic compounds, contributing to healthier indoor air quality. Manufacturing precision ensures consistent quality and dimensional accuracy, facilitating seamless installation and professional results. Modern WPC panel formulations include advanced additives for enhanced UV protection, color retention, and surface hardness, extending service life significantly beyond conventional alternatives.