Understanding Different Types of Wall Boards for Your Space

Drywall: The Standard Choice for Versatility

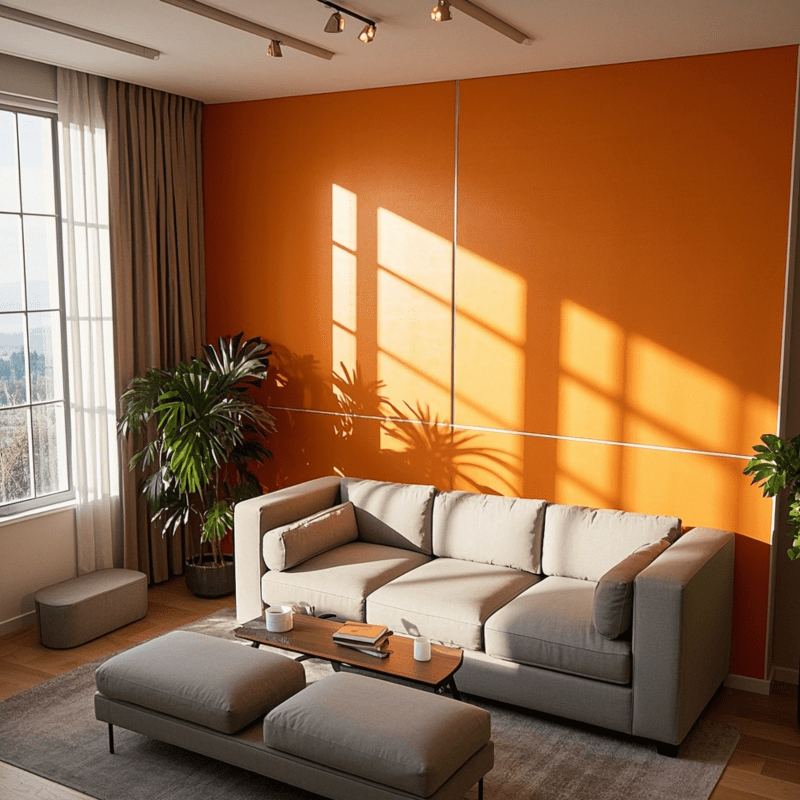

Drywall has become the go to option for walls because it works so well across different situations. People install it everywhere from homes to offices since it doesn't take much skill to put up, which explains why so many weekend warriors tackle their own renovation projects. The material comes in several thickness options too, so builders can pick what suits their specific needs whether they're reinforcing load bearing walls or just adding an extra layer somewhere else. What really stands out though is how easy it is to finish. A plain drywall surface takes paint beautifully, sticks wallpaper without issues, and even handles those fancy textured looks some decorators love these days. That flexibility means it fits right into almost any interior design scheme someone might imagine.

Cement Board: Optimal for High-Moisture Environments

Moisture problems? Cement boards might be just what builders need since they resist mold growth and hold up against water damage pretty well. They work great in those tricky spots where water is always around bathroom walls, kitchen backsplashes, even damp basement floors. When laying down tiles on these surfaces, contractors find that cement boards give a solid base that doesn't warp or crack over time. What's interesting is how these boards handle extreme temperatures too. Some folks have installed them outside without issues during hot summers and freezing winters. For anyone planning an outdoor cooking area or wanting to upgrade their patio space, cement boards stand up to all sorts of weather challenges better than many alternatives.

WPC Panels: Combining Durability and Aesthetic Flexibility

Wood Plastic Composite (WPC) panels combine good looks with lasting strength. Basically what they do is take the appearance of real wood and mix it with the toughness of plastic materials, which works really well for modern design projects. The best part about these panels? They don't require much maintenance at all, and can handle being used inside homes as well as outside on decks or patios without falling apart quickly. This means people don't have to replace them so often compared to traditional materials. Plus there are tons of different colors and surface finishes available now, giving designers plenty of options when creating interiors. Whether someone wants something simple or something fancy, WPC panels fit right into most decorating styles, which explains why they're becoming so popular across both home improvement markets and big business settings alike.

Acoustic Panels: Enhancing Sound Management

Sound absorbing panels really make a difference in places where controlling noise matters most like recording studios, office spaces, and even home entertainment rooms. They do more than just cut down on unwanted sounds though many come in all sorts of colors and textures that actually look pretty good on walls too. Installing these panels helps businesses meet those tricky sound control requirements they have to follow. The latest models use advanced materials that work wonders at reducing echo effects and cutting through constant background chatter. This makes a world of difference for anyone working or spending time in busy environments where clear communication is important.

Assessing Room Conditions and Environmental Factors

Identifying Humidity Levels for Moisture-Resistant Solutions

Getting the right humidity reading matters a lot when picking out wall boards that resist moisture. A simple hygrometer does the trick for checking how much moisture is in the air, something that helps figure out what kind of wall board works best in places where dampness tends to build up. Bathrooms and kitchens come to mind here. Putting the wrong stuff in these spaces often leads to all sorts of problems down the road. That's why taking the time to measure properly makes sense. Going with boards designed to handle moisture doesn't just stop damage from happening it actually keeps things looking good longer in those tricky spots around the house where water seems to find its way everywhere eventually.

Mold-Resistant Options for Healthier Spaces

Wall boards that resist mold help create better indoor air quality because they contain special ingredients that stop mold from growing. These boards really cut down on the dangers from floating spores and allergens that cause all sorts of health problems for people living or working in those spaces. When shopping around, look for products that have been approved by the Environmental Protection Agency. The EPA certification means these materials actually pass strict tests for safety and effectiveness. Homeowners and building managers get real assurance knowing their walls won't become breeding grounds for harmful molds that could affect everyone's health over time.

Temperature Fluctuations and Material Durability

Knowing how wall boards react to heat changes matters a lot when picking materials for places where temperatures swing wildly. Cement boards work really well because they stay stable even when temps go up and down, so there's less chance of cracks forming or the boards warping over time. Studies from construction labs show that choosing the right wall board type can cut down on heating bills since better insulation means less energy loss through walls. Builders who focus on both material durability and energy savings end up making smarter long term decisions that save money while keeping structures intact during those hot summers and cold winters we all know too well.

Evaluating Wall Board Thickness and Structural Needs

Matching Thickness to Stud Spacing for Code Compliance

Picking the correct wall board thickness matters a lot when it comes to following local building regulations and keeping walls structurally solid depending on how far apart the studs are spaced. Thin boards often work fine in spots where the framing members sit close together, but when there's more space between them, going with something thicker makes sense for better support. Getting a pro inspector involved during installation isn't just good practice, it actually helps avoid problems down the road. These experts know what looks right and what doesn't according to code requirements, which saves headaches later on and keeps everyone safe over time.

Impact Strength: Balancing Density and Functionality

Wall boards that resist impacts become really important in places where lots of people walk around all day long. When picking these boards, manufacturers need to find just the right mix of how thick they are versus how dense the material is. The goal is to make sure they hold up when bumped into while still looking good on the walls. Looking at real world examples shows us something interesting too. Buildings that chose wall boards rated properly for impact tend to last much longer before needing repairs or replacements. That makes sense why so many office spaces and school buildings now go for this kind of solution instead of cheaper alternatives that might break down faster under constant use.

Choosing the Right Material for Load-Bearing Walls

When it comes to load bearing walls, the right materials matter a lot. They need to hold up the weight of the building while meeting all those building code requirements too. Getting an expert opinion really helps figure out what kind of boards and how thick they should be for proper load support. Picking the wrong stuff can cause big problems down the road serious structural issues and potential safety risks. That's why most builders bring in professionals for these kinds of jobs where mistakes just aren't an option.

Matching Wall Board Types to Specific Applications

Kitchens and Bathrooms: Waterproof and Mold-Resistant Solutions

Kitchens and bathrooms really need wall boards that stand up against water and resist mold if we want to avoid those frustrating issues down the road. Cement boards work great here, along with that special kind of drywall designed to handle moisture. People tend to go for these options since they look good while still doing what needs to be done, so there's no compromise between appearance and actual protection from leaks. Getting this part right keeps everything looking nice in those spaces, plus makes sure the walls stay strong even after years of dealing with steam from showers and splashes from sinks.

Office Spaces: Prioritizing Acoustics and Aesthetics

Making office spaces comfortable for work really comes down to getting both the sounds right and looking good at the same time. Acoustic panels work wonders here because they cut down on bad echoes but still look great in most office settings. Some companies go for cheaper options too, which makes sense when trying to keep costs down without sacrificing too much comfort. When workers aren't constantly distracted by outside noises like traffic or neighboring conversations, their focus improves quite a bit. Many businesses have found that investing in better acoustics pays off over time, not just through happier employees but also in actual productivity gains. Offices that get this balance right tend to become places where people actually want to spend their workday instead of dreading every minute.

Garages and Utility Areas: Fire-Rated and Impact-Resistant Options

Wall boards installed in garage and utility spaces need to meet fire rating requirements and resist impacts if we want maximum safety and long lasting performance. Going for products that match industry standards cuts down on fire hazards significantly while making sure structures stay strong, especially important in these high traffic zones. Always check what local building codes say about fire protection before picking out materials for such areas. The payoff from good choices goes beyond just safety improvements. Properly selected wall boards make these workspaces function better overall, standing up to daily wear and tear without falling apart after a few months.

Fire Ratings and Safety Standards for Wall Boards

Understanding UL Fire Ratings for High-Risk Areas

UL fire ratings play a critical role when assessing wall board safety for areas prone to fires like kitchens and mechanical rooms where sparks and heat sources are common. These ratings give builders insight into how well different materials resist flames, helping them make better decisions for their projects. Looking at the various UL classifications allows professionals to pick out materials that actually stand up to fire threats effectively. Studies show buildings constructed with UL approved materials tend to suffer less damage when fires break out. For this reason, proper consideration of UL ratings remains essential for protecting homes and businesses from fire related losses.

Compliance with Local Building Codes

When picking out wall boards for a project, it really matters whether they fit local building codes since regulations change from one area to another and affect what materials can be used legally. Contractors and property owners need to keep track of code updates so their work passes safety checks and doesn't run into trouble with authorities later on. Following these rules makes buildings safer overall while making things go smoother when getting permits for new constructions or renovations. Most of the time, there will be paperwork to submit plus actual site inspections just to confirm everything meets fire safety standards too. These codes play a big part in keeping buildings safe places for everyone involved.

Best Materials for Exit Corridors and Fire-Prone Zones

The choice of materials for exit corridors and areas prone to fires plays a crucial role in maintaining safe paths for evacuation. Materials that resist fire help stop flames and smoke from spreading so quickly, which cuts down on danger during emergencies. When designing these spaces, talking to actual fire safety professionals gives real-world insights into what works best for different situations. Installing fire resistant wall boards definitely improves safety in these key areas, though it's important to check local codes and regulations first. Most buildings already have some level of protection, but upgrading to better materials often means meeting higher safety standards while making occupants feel more secure.

Installation Tips for Seamless, Professional Results

Tapered-Edge Sheets for Invisible Seams

Tapered edge sheets make a real difference when it comes to how those seams and joints look after installing wall boards. When done properly, walls end up smooth enough for painting or texturing without all those ugly gaps showing through. Contractors who take the time to get this right see better results than just slap-and-go methods. The payoff? Cleaner finishes that don't need constant touch ups later on. Plus, jobs tend to wrap up faster since there's less backtracking required to fix poor joins. Everyone wins in the long run from both an aesthetic standpoint and project timeline perspective.

Joint-Compound Techniques for Level-5 Finishes

Getting those level 5 finishes right really depends on good joint compound work, especially when planning to apply high gloss paints later. The whole process basically comes down to applying and sanding the joint compound correctly. Most people find that spending extra time on this step makes all the difference in how smooth and professional the finished wall looks. Sure, it takes some getting used to and plenty of trial runs before things start looking great, but trust me when I say that putting in the extra hours pays off big time in the end result.

Essential Tools for Efficient Installation

Getting the proper tools makes all the difference when installing wall boards. A good set includes things like a taping knife for smoothing joints, a reliable power drill with various bits, and at least one decent square level to keep everything straight. When someone spends money on decent quality gear instead of cheap alternatives, they'll notice how much faster jobs get done and how much better the finished product looks. Before starting any project, it pays to organize everything ahead of time. Lay out the tools within easy reach, stack the panels neatly somewhere accessible, and maybe even label where each piece goes. This kind of prep work cuts down on frustration later on and keeps the whole installation going without unnecessary stops and starts.

Cost Efficiency: Minimizing Waste and Labor

Calculating Board Sizes to Reduce Offcuts

Getting board sizes right when measuring room dimensions helps cut down on waste during installation work. Precise measurements mean fewer leftover pieces lying around after the job is done, which saves money on materials as well as what it costs to get rid of all that scrap wood. Design programs make it easier to figure out exactly how much material goes where in different parts of the space. Taking this kind of careful approach before starting any project actually makes sense for several reasons at once. It keeps resources from going to waste while also making good economic sense since nobody wants to pay extra for stuff they don't need in the first place.

Bulk Purchasing and Storage Considerations

When someone buys wall boards in large quantities, they usually end up paying less per piece and won't run short mid-project. But here's something important nobody mentions much these days: finding good storage space becomes critical so those boards don't get warped or damaged sitting around waiting for installation. Proper storage actually makes all the difference in keeping those boards usable months later instead of throwing them away because they got bent out of shape. And let's face it, planning purchases ahead of time saves headaches down the road. Contractors who map out their material needs tend to spend smarter money overall while still getting decent quality products for their clients' homes.

Labor-Saving Strategies for DIY and Contractors

Saving time on labor makes projects run smoother for everyone from weekend DIYers to full time contractors working on big jobs. Take prefab parts as an example they speed things up a lot while making sure everything looks consistent when put together. When workers get proper training in how to install things right, they finish faster because they know what they're doing instead of fumbling around. Software apps and other tech gadgets really help keep everyone on the same page about what needs done next, which means fewer delays and better overall results. All these approaches combined cut down on how much money gets spent on labor while getting projects completed quicker without sacrificing quality.

FAQ Section

What are the best wall boards for high-moisture areas?

Cement boards and moisture-resistant drywall are ideal for high-moisture areas like bathrooms and kitchens, offering durability and protection against water damage.

How do I choose the right wall board for sound management?

For sound management, acoustic panels are recommended, as they help reduce noise and enhance sound quality in spaces like studios and offices.

Are there wall boards specifically designed for fire safety?

Yes, fire-rated wall boards are available, suitable for areas prone to fire risks such as garages and utility rooms, helping reduce fire hazards and enhance safety.

How can I minimize waste during wall board installation?

Accurate measurement and planning using design software can reduce waste, while bulk purchasing and proper storage can help manage resources efficiently.

Why are tapered-edge sheets used in installation?

Tapered-edge sheets make seams and joints less visible, providing a professional and polished finish to the wall surface.

What tools are essential for wall board installation?

Essential tools for wall board installation include taping knives, power drills, and square levels to ensure a streamlined and professional process.

Table of Contents

- Understanding Different Types of Wall Boards for Your Space

- Assessing Room Conditions and Environmental Factors

- Evaluating Wall Board Thickness and Structural Needs

- Matching Wall Board Types to Specific Applications

- Fire Ratings and Safety Standards for Wall Boards

- Installation Tips for Seamless, Professional Results

- Cost Efficiency: Minimizing Waste and Labor

-

FAQ Section

- What are the best wall boards for high-moisture areas?

- How do I choose the right wall board for sound management?

- Are there wall boards specifically designed for fire safety?

- How can I minimize waste during wall board installation?

- Why are tapered-edge sheets used in installation?

- What tools are essential for wall board installation?