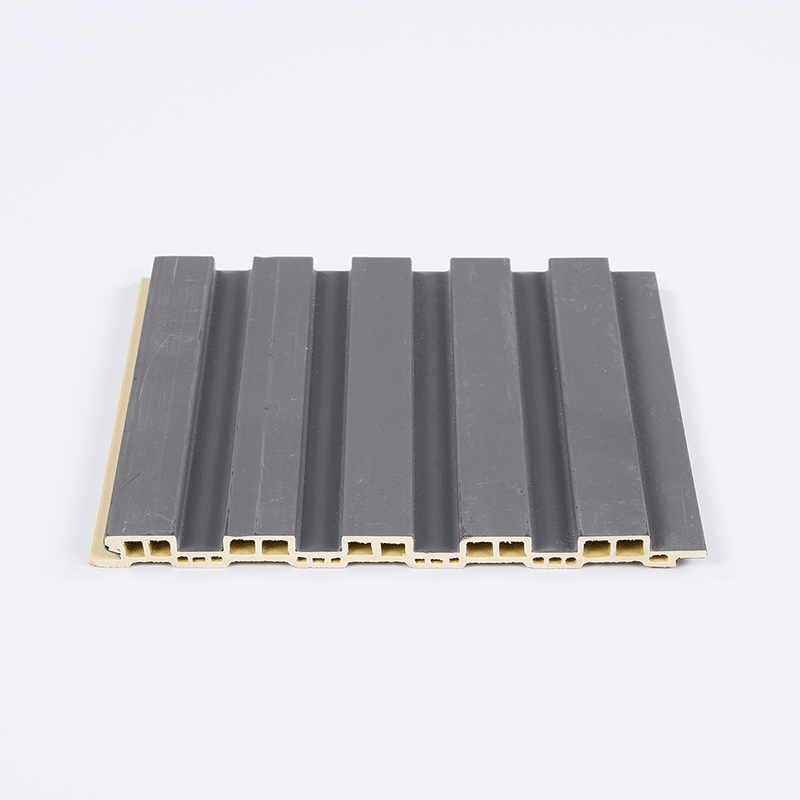

קיר לוח עץ

פנלי עץ לקיר מייצגים גישה מהפכנית לבניית קירות פנימיים וחיצוניים, המשלבת את היופי של עץ מסורתי עם טכניקות הנדסיות מודרניות. חומר הבנייה החדשני הזה כולל פנלים מוערטים מעץ, שתוכנו במיוחד ליישומים בקיר, ומציע יציבות מבנית גבוהה יותר ומראה אסתטי. מערכות פנלי עץ לקיר כוללות שכבות מרובות של חומרי עץ מעובדים, ויוצרות מבנה מורכב שמביא לביצועים משופרים בהשוואה לבנייה מסורגת מסורגת. תהליך הייצור כולל חיתוך מדויק, הדבקה וטכניקות סיום שיוצרות פנלים יציבים לממדיהם והעומדים להתקנה. לפנלים יש חיבורים מסוג "שן וחריץ" או מערכות נעילה שמבטיחות הרכבה חלקה ועמידות לאורך זמן. פנלי עץ לקיר ממלאים מספר תפקידי: תמיכה מבנית, שיפור בידוד, ניהול רטיבות וסיום אסתטי – הכול במערכת משולבת אחת. התכונות הטכנולוגיות של פנלי עץ לקיר כוללות טיפולים מתקדמים למניעת בליעה, אופטימיזציה של ביצועי חום וכיסויים עמידים באש כשנדרש. פנלי עץ לקיר מודרניים כוללים פרקטיקות של ייעור בר-קיימא ודבקים ידידותיים לסביבה, מה שהופך אותם לבחירה סביבתית מודעת עבור פרויקטים בניה. המידות התקניות והאופי המוקדם של פנלי עץ לקיר מקטינים משמעותית את זמן ההתקנה ועלויות עבודה בהשוואה לשיטות בנייה מסורגות מסורתיות. פעולות בקרת איכות בתהליך הייצור מבטיחות מאפייני ביצועים אחידים בכל הפנלים, ומסירים את השונות שנלווית לעצי סחורה טבעיים. יישומי פנלי עץ לקיר משתרעים על פני בנייה מגורים, מבנים מסחריים, מתקנים מוסדיים ובניינים מיוחדים הדורשים גם יכולת פעולה וגם מראה אסתטי. הגמישות של פנלי עץ לקיר מאפשרת התאמה אישית במונחים של kếtני משטח, בחירת מיני עץ ואפשרויות סיום, כדי להתאים דרישות ארכיטקטוניות ורצונות עיצוב מסוימים.