geavanceerd SPC wandpaneel grootserige productie

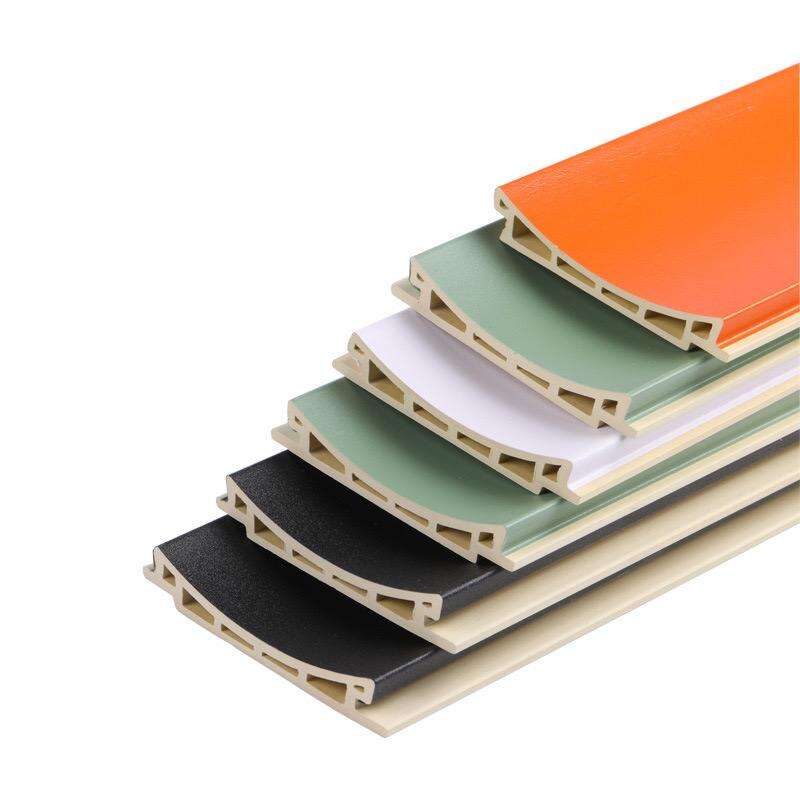

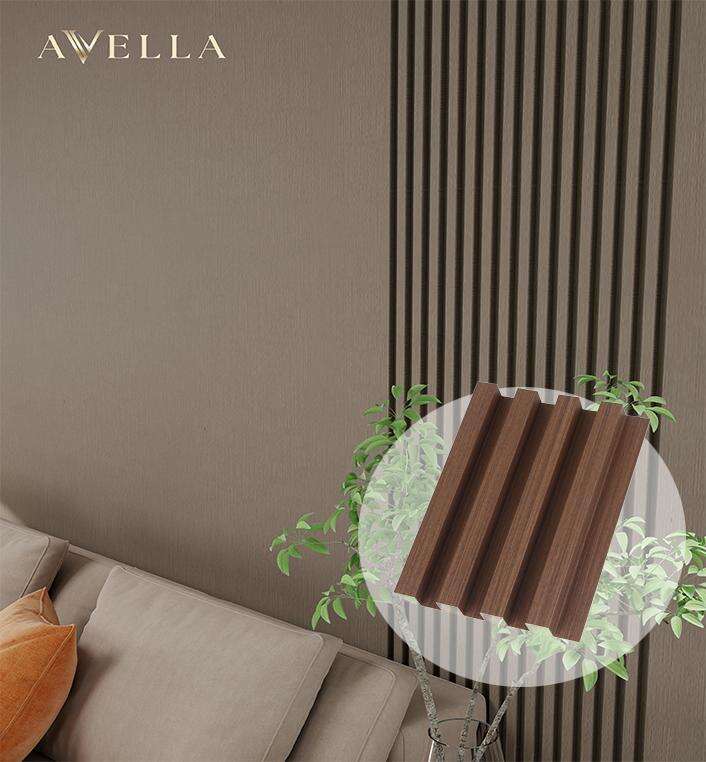

Geavanceerde SPC-wandpaneel grootseriепroductie vertegenwoordigt een revolutionaire aanpak voor de productie van steen-kunststofcomposiet wandpanelen, waarbij geavanceerde technologie wordt gecombineerd met efficiënte massaproductiemogelijkheden. Dit verfijnde productieproces maakt gebruik van ultramoderne apparatuur en innovatieve technieken om hoogwaardige wandpanelen in ongekende volumes te produceren, teneinde te voldoen aan de groeiende wereldwijde vraag naar duurzame en esthetisch aantrekkelijke oplossingen voor binnenshuiswanden. Het geavanceerde SPC-wandpaneel grootseriепroductiesysteem integreert meerdere productiefasen, waaronder materiaalvoorbereiding, extrusie, calanderen, oppervlaktebehandeling en kwaliteitscontrole, allemaal geoptimaliseerd voor maximale efficiëntie en consistente productiekwaliteit. De belangrijkste functies van dit productiesysteem omvatten geautomatiseerde menging van materialen, nauwkeurige temperatuurregeling tijdens het extruderen, meerlagige laminatieprocessen en uitgebreide kwaliteitsborgingsprotocollen. Technologische kenmerken zijn onder andere computergestuurde productielijnen, real-time bewakingssystemen, geavanceerde koelsystemen en geautomatiseerde snij- en verpakkingsystemen die zorgen voor dimensionele nauwkeurigheid en een consistente oppervlakteafwerking. Het productieproces begint met het zorgvuldig mengen van kalksteenpoeder, polyvinylchloridehars en stabilisatoren, gevolgd door extrusie bij hoge temperatuur waarmee de kernsubstraat wordt gevormd. Vervolgens worden decoratieve lagen met realistische hout-, steen- of abstracte patronen aangebracht via geavanceerde print- en reliëftechnieken. Toepassingen van deze wandpanelen strekken zich uit over de woningbouw, commerciële toepassingen en instellingen, zoals hotels, kantoren, winkelruimtes, zorginstellingen en moderne woningen. Het geavanceerde SPC-wandpaneel grootseriепroductiesysteem stelt fabrikanten in staat schaaleffecten te realiseren terwijl strenge kwaliteitsnormen worden gehandhaafd, wat resulteert in kostenefficiënte oplossingen voor interieurarchitecten, aannemers en vastgoedontwikkelaars. Deze productieaanpak ondersteunt maatwerk, waardoor diverse diktes, oppervlaktestructuren en decoratieve patronen mogelijk zijn om tegemoet te komen aan uiteenlopende architectonische eisen en esthetische voorkeuren in verschillende marktsegmenten.