Szeroki zakres produktów i możliwości dostosowywania

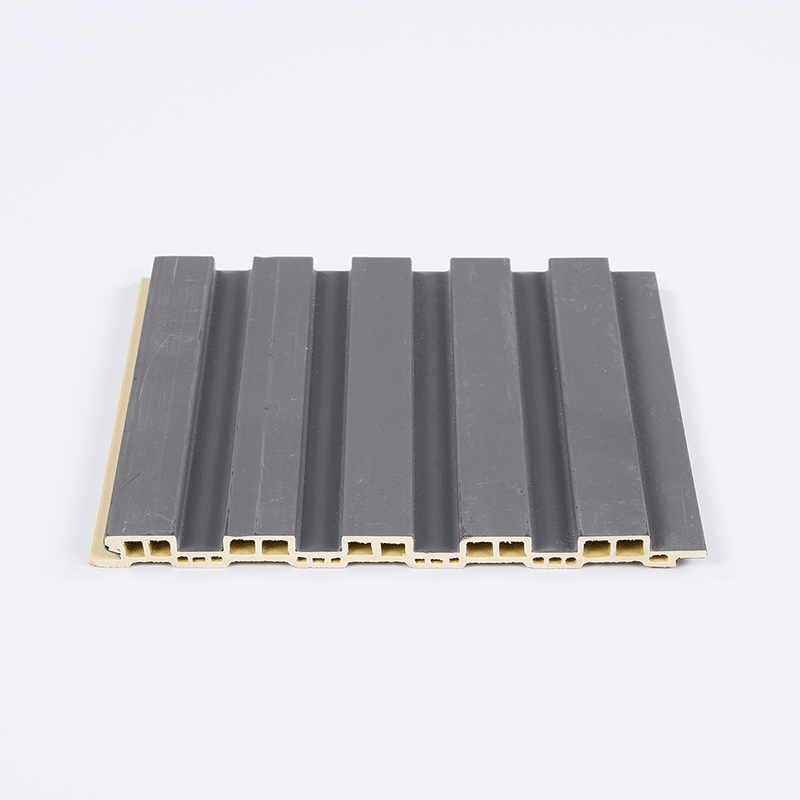

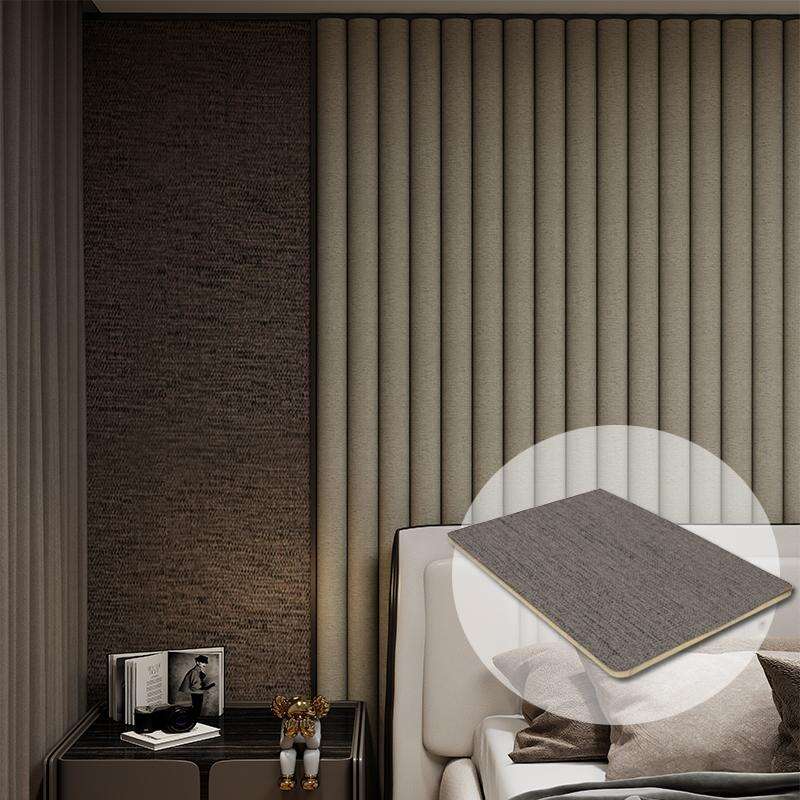

Ustaleni producenci podłóg SPC oferują szeroki asortyment produktów, które spełniają różne preferencje klientów, wymagania aplikacyjne i względy budżetowe, zapewniając rozwiązania dla praktycznie każdego projektu podłogowego mieszkalnego lub komercyjnego. Producenci ci utrzymują kompleksowe kolekcje zawierające różne rozmiary desek, tekstury powierzchni, palety kolorów i specyfikacje wydajności, które umożliwiają klientom znalezienie idealnych dopasowań do ich specyficznych wizji projektowych i potrzeb funkcjonalnych. Możliwości dostosowywania oferowane przez progresywnych producentów podłóg SPC obejmują opracowanie wzoru na zamówienie, niestandardowe usługi dopasowywania kolorów i specjalistyczne zabiegi powierzchniowe, które tworzą unikalne rozwiązania podłogowe dla wymagających klientów i Profesjonalni producenci podłóg SPC zazwyczaj organizują swoje linie produktów w różne kategorie, takie jak kolekcje mieszkalne, serii komercyjne i luksusowe opcje premium, z których każda została zaprojektowana z odpowiednimi właściwościami wydajności dla zamierzonych zastosowań. Różnorodność projektowania oferowana przez innowacyjnych producentów podłóg SPC obejmuje replikacje tradycyjnych gatunków drewna, współczesne wzory kamienne, abstrakcyjne projekty artystyczne, a nawet niestandardowe grafiki, które przekształcają podłogi w charakterystyczne element Producenci współpracują z projektantami wnętrz i architektami, aby opracować ekskluzywne kolekcje, które odzwierciedlają aktualne trendy projektowe, zachowując jednocześnie standardy techniczne wymagane do wymagających zastosowań. Opcje grubości dostępne od kompleksowych producentów podłóg SPC wahają się od standardowych specyfikacji mieszkalnych po klasy komercyjne ciężkich urządzeń, zapewniając odpowiednie właściwości strukturalne dla różnych poziomów ruchu i warunków podłogowych. Konsistencja kolorów stanowi kluczową zaletę oferowaną przez renomowanych producentów podłóg SPC, którzy utrzymują rygorystyczne protokoły dopasowywania kolorów w ramach serii produkcyjnych, aby zapewnić płynną instalację w dużych projektach. Opcje wykończenia powierzchni oferowane przez wszechstronnych producentów podłóg SPC obejmują gładkie, teksturowane, ręcznie skrapiane i szczotkowane efekty, które zwiększają autentyczność wizualną i zapewniają odpowiednią odporność na poślizg w różnych środo Specjalistyczne kolekcje od wiodących producentów podłóg SPC często charakteryzują się ulepszonymi cechami, takimi jak leczenie przeciwdrobnoustrojowe, ulepszone właściwości akustyczne lub zaawansowana odporność na plamy, które odpowiadają na specyficzne wymagania klient