anpassning av spc-väggpaneler

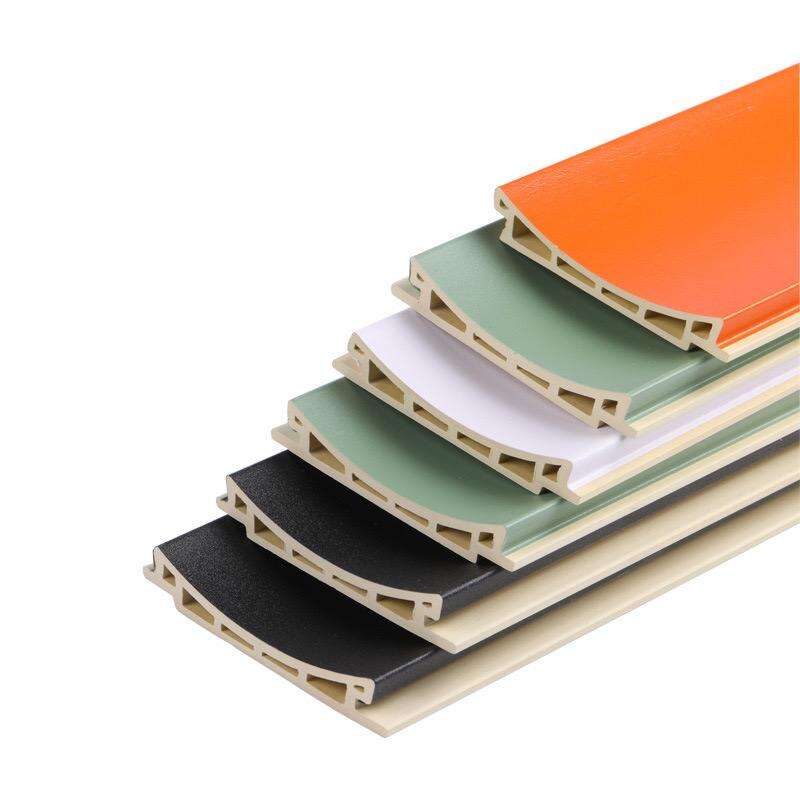

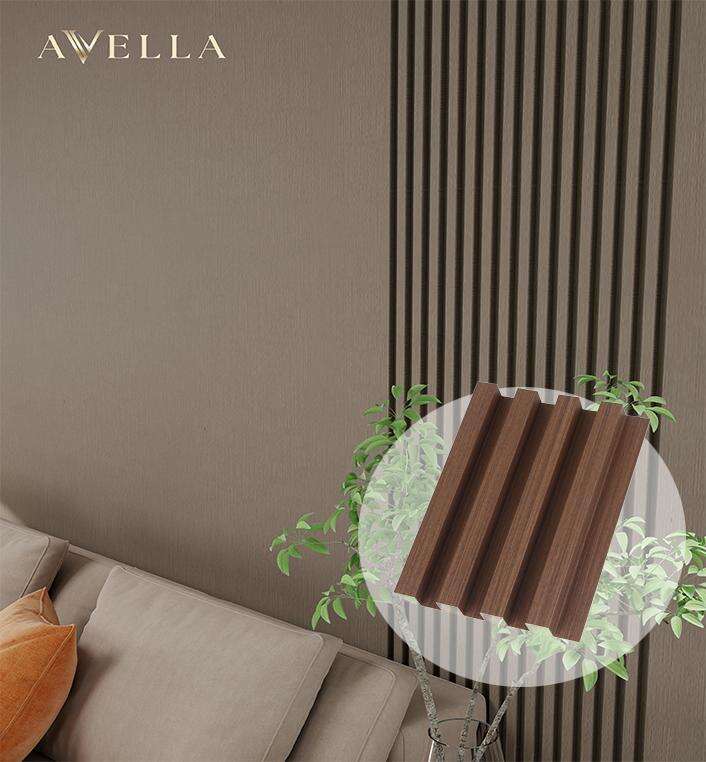

Anpassning av SPC-väggelement representerar en revolutionerande metod inom inredningsdesign och byggande, vilket ger fastighetsägare oöverträffad flexibilitet att skapa personliga utrymmen som speglar deras unika estetiska preferenser och funktionella krav. Stone Plastic Composite-teknik utgör grunden för dessa innovativa lösningar för väggbeklädnad, där kalkstenspulver, polyvinylklorid och stabiliseringsmedel kombineras för att skapa slitstarka, mångsidiga paneler som kan anpassas efter specifika projektbehov. Anpassningsprocessen omfattar olika aspekter såsom storlekar, ytstrukturer, färgvariationer och ytbehandlingsalternativ, vilket gör att arkitekter och designers kan förverkliga sin exakta vision utan kompromisser. Panelerna innefattar avancerade tillverkningstekniker som möjliggör exakt dimensionell kontroll, vilket säkerställer perfekt passning och sömlös installation i mångskiftande arkitektoniska tillämpningar. De tekniska egenskaperna hos anpassade SPC-väggelement inkluderar vattentät konstruktion, brandmotstånd och förbättrad akustikprestanda, vilket gör dem lämpliga för bostäder, kommersiella lokaler och institutionella miljöer. Anpassningsmöjligheterna sträcker sig bortom estetiska element till att inkludera funktionella modifieringar såsom integrerade kabelföringsystem, fästpunkter för armatur och specialiserade kantprofiler för specifika installationskrav. Tillverkningsprocesser använder datorstyrd maskinutrustning för att uppnå konsekvent kvalitet och precision vid specialbeställningar, samtidigt som de inhemska fördelarna med standard SPC-material bevaras – exempelvis dimensionsstabilitet, slagstyrka och låg underhållsbehov. Tillämpningar finns inom hotell- och restaurangbranschen, sjukvårdsanläggningar, utbildningsinstitutioner, butikslokaler och lyxbostadsprojekt där standardpaneler inte uppfyller specifika designkrav. Anpassningstjänsten inkluderar omfattande designrådgivning, utveckling av tekniska specifikationer samt kvalitetssäkrande tester för att säkerställa att varje anpassad panel uppfyller prestandakraven samtidigt som den önskade estetiken uppnås. Avancerade trycktekniker möjliggör reproduktion av naturliga material, konstnärliga motiv eller företagsmärkeselement direkt på panelytorna, vilket skapar helt unika installationer som uppfyller både funktionella och dekorativa syften.