spc väggpanel fabrik

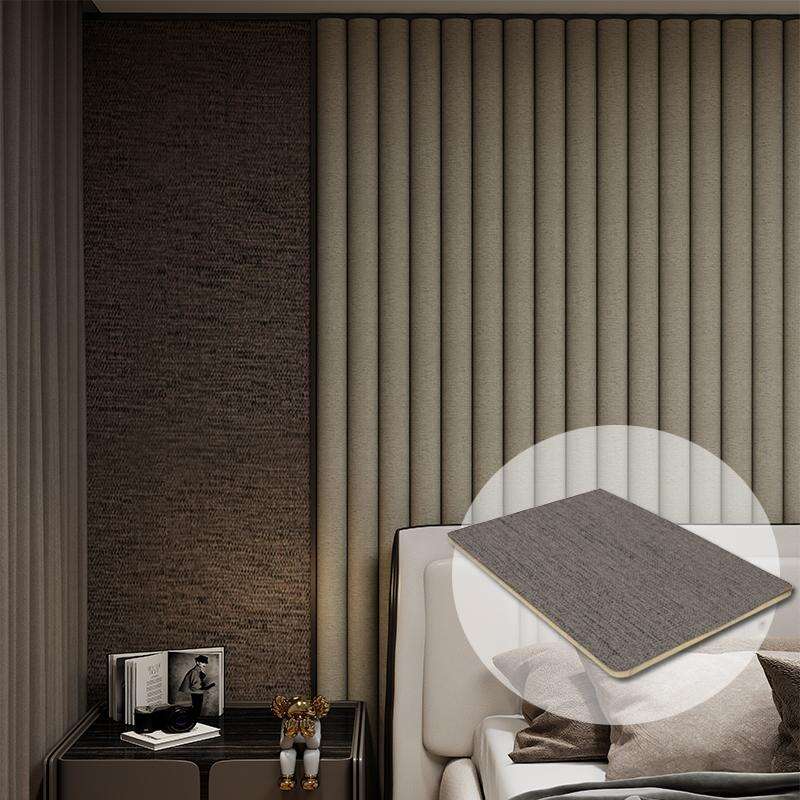

SPC-väggpanelanläggningen representerar en modern tillverkningsanläggning som är specialiserad på produktion av stenplastkompositväggpaneler, vilka har revolutionerat inredningsdesign och byggnadsapplikationer. Dessa specialiserade produktionscenter kombinerar avancerad teknik med innovativa material för att skapa slitstarka och mångsidiga väggbeklädnadslösningar som uppfyller moderna arkitektoniska krav. SPC-väggpanelanläggningen använder sofistikerade extruderingsprocesser, precisionsklippningsutrustning och kvalitetskontrollsystem för att tillverka paneler med överlägsna prestandaegenskaper. Den främsta funktionen hos en SPC-väggpanelanläggning innebär omvandling av råmaterial såsom kalkstenspulver, polyvinylkloridharts och stabiliseringsmedel till färdiga väggpaneler genom kontrollerad uppvärmning, blandning och formsprutning. De tekniska egenskaperna hos dessa tillverkningsanläggningar inkluderar automatiserade produktionslinjer utrustade med tvåskruvsextruderare, kallanderapparater, UV-beklädningsapplikationer och digitala trycksytem som möjliggör realistisk strukturåtergivning. Kvalitetssäkringsprotokoll inom SPC-väggpanelanläggningen säkerställer konsekvent tjocklek, dimensionsstabilitet och ytans kvalitet i alla produkter. Anläggningen inkluderar vanligtvis miljökontroller för att upprätthålla optimala temperatur- och fuktighetsnivåer under hela produktionscykeln. Moderna SPC-väggpanelanläggningar har också integrerade testlaboratorier där produkter utsätts för rigorösa utvärderingar av slitstyrka, brandmotstånd och miljööverensstämmelse. Applikationer för SPC-väggpaneler tillverkade i dessa anläggningar omfattar bostads-, kommersiella och industriella sektorer, inklusive badrumsinstallationer, köksskyddspaneler, accentväggar och kommersiella utrymmen med hög trafik. Produkternas mångsidighet från en SPC-väggpanelanläggning gör dem lämpliga både för nybyggnation och renovering, och erbjuder arkitekter och designers flexibla lösningar för att skapa distinkta inomhusmiljöer.