Çeşitli Uygulamalar için Özel Yapılandırılabilir Tasarım Çözümleri

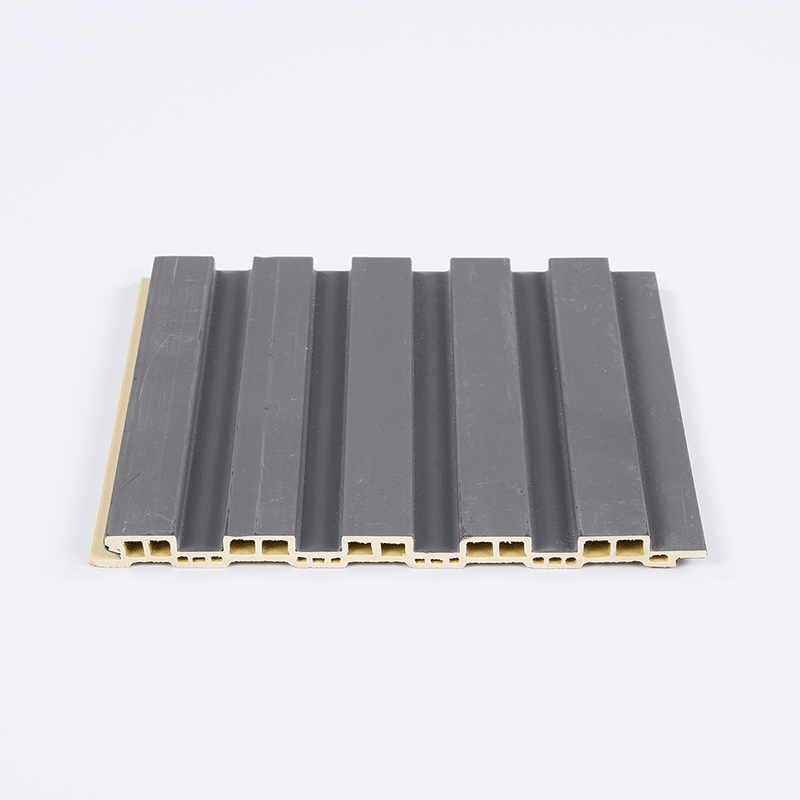

Izgara duvar paneli imalatı, mimarların, tasarımcıların ve bina sahiplerinin özel proje gereksinimlerine ve estetik tercihlerine mükemmel bir şekilde uyan benzersiz çözümler yaratmalarını sağlayan benzeri görülmemiş özelleştirme yetenekleri sunar. Tasarım esnekliği, malzeme seçimi ile başlar ve her biri dayanıklılık, görünüm ve çevresel performans açısından farklı özellikler sunan alüminyum alaşımları, paslanmaz çelik, hava koşullarına dayanıklı çelik ve kompozit malzemeler arasında seçimler sunar. Perforasyon kalıpları, hava akışı hızlarının, ışık iletim yüzdelerinin ve görsel tarama efektlerinin kesin kontrolünü elde etmek için özelleştirilebilir. Seçenekler basit dairesel veya kare deliklerden çarpıcı görsel efektler yaratan karmaşık geometrik tasarımlara ve sanatsal kalıplara kadar değişir. Panel boyutları, düzensiz açıklıklara, eğri yüzeylere ve standart olmayan mimari özelliklere uygun olarak, standart raf dışı ürünlerle çözülmesi imkansız olan tam özelliklere göre üretilir. Yüzey işleme seçenekleri arasında değirmen işleme, birden fazla renkte anodlama, neredeyse sınırsız renk seçeneklerinde toz kaplama ve bina tasarım temalarını tamamlayan ahşap tanesi efektleri veya metal dokular gibi özel işlemler bulunur. Montaj sistemleri, beton, çelik çerçeve, duvar sistemi veya perde duvar sistemlerine monte edilebilir, bina hareketini ve termal genişlemesini karşılayan ayarlanabilir bağlantılar için seçeneklerle belirli yapısal koşullara uygun olarak tasarlanmıştır. Performans özellikleri, kıyı ortamları için daha fazla korozyon direnci, aşırı sıcaklık bölgelerinde daha iyi termal performans ve yüksek kirlilik oranına sahip kentsel alanlar için özel kaplamalar ile belirli iklim koşulları için optimize edilebilir. Entegrasyon yetenekleri, ızgara panellerinin LED aydınlatma sistemleri, işaretleme montaj donanımı veya akıllı bina uygulamaları için sensör ekipmanları gibi ek işlevsel öğeleri dahil etmesini sağlar. Modüler tasarım ilkeleri, panellerin çeşitli yapılandırmalarda birleştirilmesini, kurulum esnekliğini ve gelecekteki modifikasyon yeteneklerini korurken daha büyük montajlar oluşturmasını sağlar. Dokümanlama desteği, her özel yapılandırmaya uyarlanmış ayrıntılı çizimler, kurulum talimatları ve performans özelliklerini içerir, bu da projeyi başarılı bir şekilde tamamlamayı ve uzun vadeli performans memnuniyetini sağlar.