bestående spc väggpanel anpassad produktion

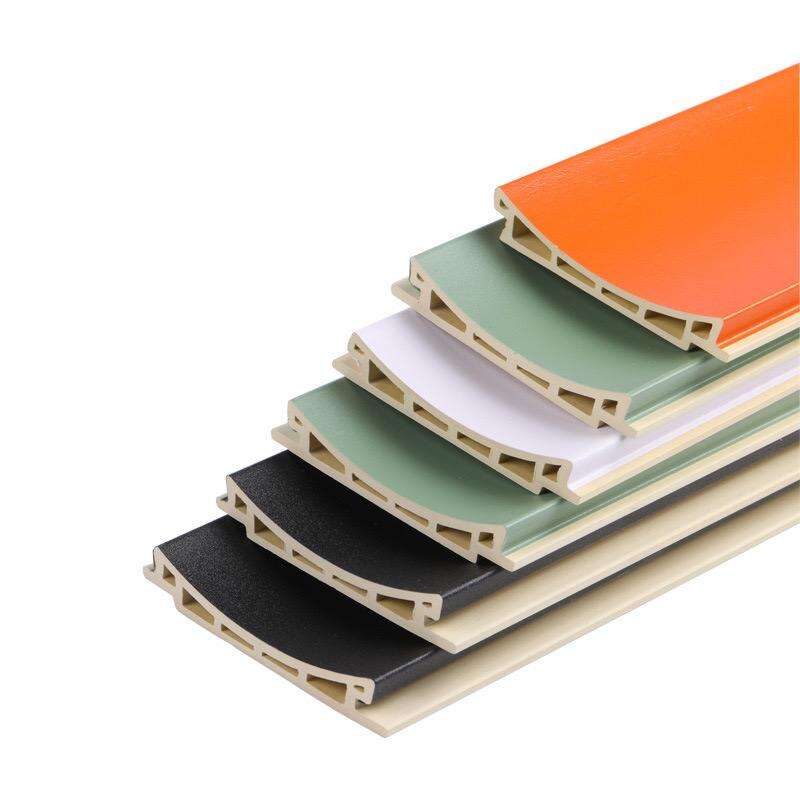

Hållbar tillverkning av anpassade SPC-väggelement representerar en revolutionerande framsteg inom modern bygg- och innemiljödesign. SPC, som står för Stone Plastic Composite (stenplastkomposit), kombinerar stens hållbarhet med plastens flexibilitet för att skapa väggelement som presterar utmärkt i både bostäder och kommersiella miljöer. Den anpassade tillverkningsprocessen gör att tillverkare kan skräddarsy panelerna enligt specifika designkrav, mått och estetiska preferenser, samtidigt som de bevarar den inneboende styrka och pålitlighet som SPC-material är kända för. De främsta funktionerna hos hållbara anpassade SPC-väggelement inkluderar exceptionell fuktmotståndighet, överlägsen slagstyrka, utmärkt termisk stabilitet samt långsiktig dimensionsstabilitet. Panelerna fungerar som skydd mot yttre påfrestningar samtidigt som de förbättrar det visuella intrycket i inomhusmiljöer. De tekniska egenskaperna omfattar avancerade tillverkningsprocesser med högtryckslaminering, precisionscylindersystem och specialiserade ytbehandlingar. Produktionen innebär att kalkstenspulver, polyvinylklorid och stabiliseringsmedel kombineras under kontrollerade förhållanden för att skapa en homogen kärnstruktur. Med anpassad produktion kan tillverkare integrera olika strukturer, färger, mönster och ytfinish som uppfyller specifika projektkrav. Tillämpningsområden för hållbar tillverkning av anpassade SPC-väggelement omfattar flera sektorer, såsom vårdinrättningar, utbildningsinstitutioner, hotell och restauranger, butiker samt bostadsfastigheter. Panelerna är särskilt värdefulla i områden som kräver ofta rengöring, hög trafik och miljöer där traditionella material snabbt kan försämras. Anpassningens mångsidighet gör att arkitekter och designers kan genomföra kreativa lösningar samtidigt som de säkerställer efterlevnad av byggregler och säkerhetsstandarder. Tillverkningsprocessen inkluderar kvalitetskontroll åt varje steg för att garantera konsekvent prestanda och utseende i hela produktserier.